Versalis GPPS- HIPS products

The main characteristics common to the GPPS and HIPS grades are:

- Easy processing

- Resistance to cracking under stress

- High chemical resistance to oils, fats and chemical agents

- Deep draw thermoforming

- Heat resistance

- Good mechanical strength

- Easy flow

- High stiffness

- Excellent impact strength

- Glossy

Applications

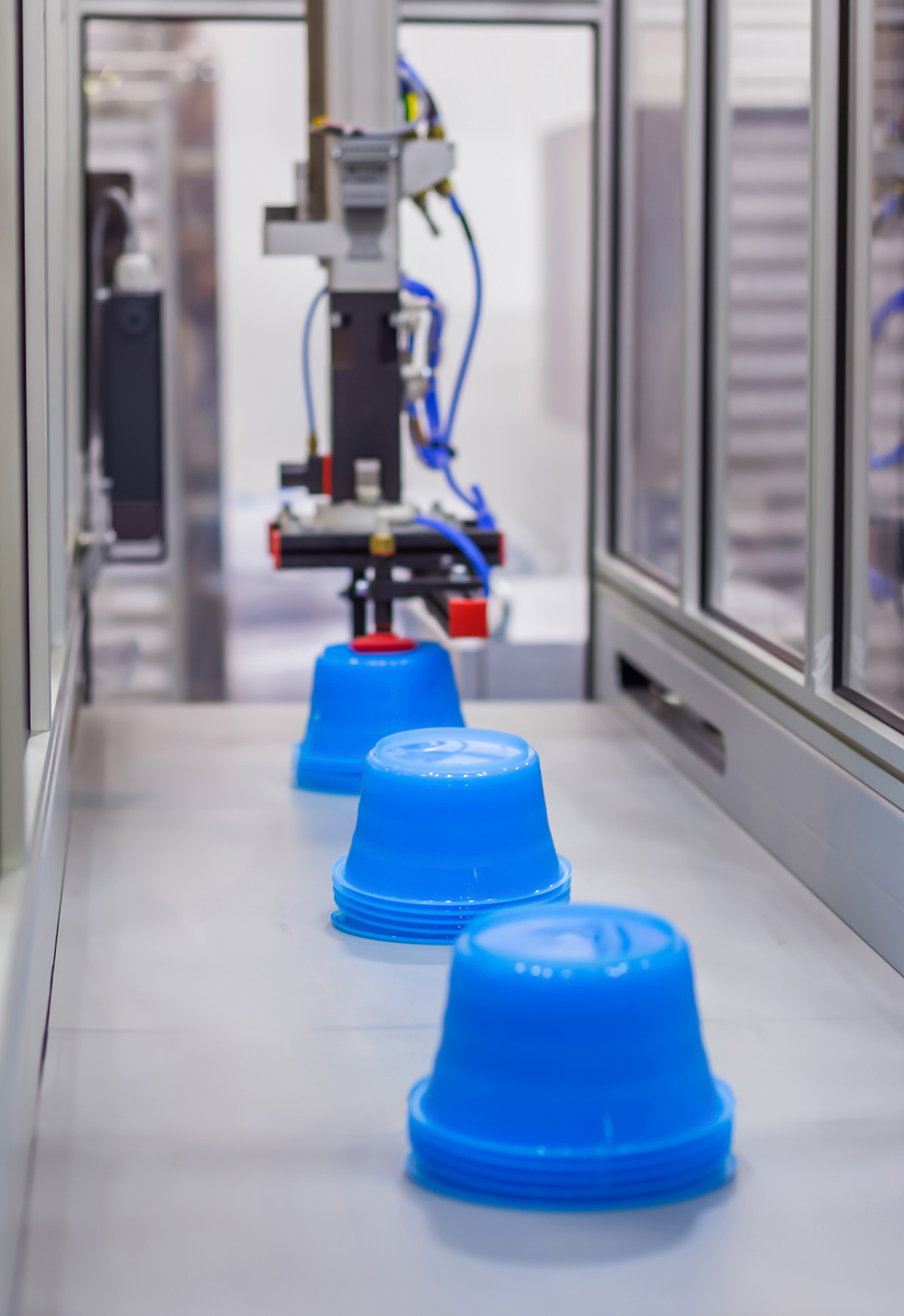

- Uses with dairy products: Yoghurt pots, fromage frais packaging, ice cream boxes

- Catering: Containers and films for food use

- Fresh food: Trays and small boxes

Various transformation processes:

– Cast extrusion:

shaping the melted mass, plasticising it and homogenising it in the extruder results in an end product with a high level of transparency, gloss and stiffness.

– Extrusion blow moulding:

The melted polymer passes through a ring extruder.

This generates a tube of relatively small diameter, which is immediately expanded with blown air and stretched through traction. The film cools and solidifies.

It can then be folded between drawing rollers.

– Form Fill Seal (FFS):

Widely used in the dairy sector, this is a high-productivity manufacturing process.

Depending on the intended use, the sheet can be made up of several layers.

– Two-sided sheet:

Certain characteristics of the sheet can be improved with this technology (by drawing a moulded sheet): – transparency, mechanical properties, oxygen and water vapour permeability.

– Thermoforming:

Produces items by heating semi-finished products until they reach the rubber phase (through plastic deformation).

End products produced with thermoforming include coffee cups and yoghurt pots.